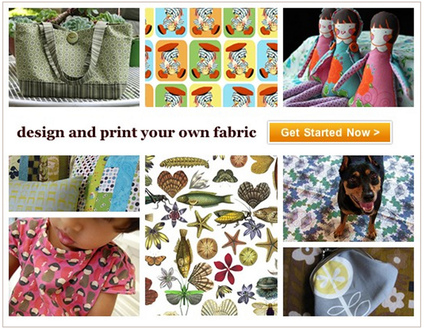

To enter, leave a comment about Spoonflower—perhaps your favorite Spoonflower print or a suggestion for their next design contest—by Wednesday, February 23nd, 2011, at noon EST.

And now, here is the Q&A with Stephen Fraser, with a little help from his wife, Kim. Enjoy!

Q: So, you are up to 100,000 strong in the Spoonflower community, and the site is positively brimming with talent from all over the world. Could you ever have envisioned this three years ago? What were your original goals for Spoonflower?

Fraser: Spoonflower came about because of a conversation I had one night with my wife, Kim, who wondered why she couldn't get her own fabric design printed to make curtains. Being an Internet guy, I found it strange that there wasn't already service that allowed people to create their own textiles, so I approached a friend, Gart Davis, about the idea and we ended up launching the first version of the Spoonflower site around May of 2008.

The Spoonflower community has grown to well over a 100,000 people at this point, which is a huge thrill for us. We keep a map on the wall—printed on fabric of course—with pins in it showing all 114 countries to which we've shipped fabric so far. When we got started we were hopeful, of course, that the idea of custom printed fabric would catch on, but from a personal standpoint it's a bit dizzying to look at where we are now compared with where we started. Building a manufacturing business from scratch using our own limited funds has been a learning experience full of challenges at every turn.

The goal with which we started was relatively simple. We wanted to take digital textile printing technology—which made it possible to print fabric with no minimum—and to make it accessible to regular people. By "regular people" I mean crafters—people like my wife Kim—who have a passion for fabric and making things but who would never spend $50 a yard to use a specialty printing service for custom fabric. To make that possible we had to solve two central problems. The first was to figure out a way to produce digitally printed fabric quickly and relatively inexpensively. The second challenge was to develop a web-based process for creating and ordering fabric with your own design that was simple and easy to use. So that's what my business partner Gart Davis and I set out to do when we started. We had a head start on the second challenge because we'd both worked for an Internet business that offered print on demand products before (Lulu.com), but we really had a lot to learn about textiles and handling digital printers. But in terms of learning the trade, we had the good fortune to live in an area with a lot of expertise not only in textiles, but also in digitally printed textiles specifically. The NC State College of Textiles is nearby, and so is a not-for-profit organization called [TC]2, which serves the sewn goods industry. They were extremely helpful to us as we went about learning what we needed to know to develop Spoonflower.

Q: Where did the name Spoonflower come from?

Fraser: Spoonflower is the common name of an endangered wildflower that is native to the Southeast and grows on the edges of swamps and bogs. Kim and I ran across the name several years ago when we were figuring out what kinds of plants we could use in the rain garden in our backyard. We thought it would be the perfect name for a business that was all about self-expression and individuality.

Q: The Spoonflower story sort of reminds me of the story of Butterick patterns. One night, Ebenezer Butterick’s wife mentioned that it would be great to have sewing patterns that were already graded (sized). Butterick, a tailor by trade, saw the light bulb and started Butterick patterns! How long was it from the time you had this conversation with Kim until Spoonflower launched, and what did you do to plant the seeds for your business?

Fraser: The conversation about Kim's curtains happened in the fall of 2007, when Kim was pregnant with our third daughter, who was born that December. I think Gart and I sat down for coffee in early January 2008 and decided to pursue the idea of a print on demand fabric business. We started by asking crafters what they thought of the idea and posting a short survey online, which was then picked up and linked by several crafting blogs, including Sew Mama Sew. Within a few days we had over 500 responses to the survey. What was clear to Gart and I immediately was that our wives were not the only ones excited about the idea of printing custom fabric—lots of people wanted us to create this service.

First we set up a blog to record our progress and then we went about the process of starting to build the software that would allow Spoonflower to exist. The buzz about Spoonflower spread from blog to blog through the spring and summer and by the time we opened up the site to one and all in October of 2008 we had thousands of people—not just signed up to use Spoonflower—but cheering us on.

Q: You mentioned that you had previously worked for Lulu.com, where you gained experience in print-on-demand. What was the learning curve like when you started working with printing fabric?

Fraser: Helping develop Lulu taught us a lot about giving people the power to publish their own creations online. We understood the landscape in the sense that we knew that our task was to provide tools that enable a creative community to accomplish various things associated with the central task of creating custom fabric. We knew that we always had to give people control over their own work, how to manage and nurture a community of people who want to share their creativity with one another, and how to encourage people to connect with others and discover new designs.

Having said that, the Spoonflower experience has been wildly different from Lulu in terms of the resources available to us. Lulu was a technology company that from the beginning had significant financial backing, whereas Spoonflower was a startup founded by two guys without a lot of money. Where Lulu had a team of software engineers, we had one (Gart). But the part we really had to learn from scratch was the fabric printing. The story of our efforts master digital textile printing would take a long time to relate, but suffice to say it has required a lot of persistence. What kept us going even though the dark days when we thought we'd go bankrupt before we had it figured out was the enthusiasm of the Spoonflower community—customers who were so passionate and excited to have the chance to create their own fabrics and who desperately wanted us to succeed. When we started out, Kim had to explain to me the difference between linen and cotton. I'm slightly more educated than that now.

Q: So, does being around all of this fabulous fabric all day make you want to sew?

Fraser: Yes! I am always imagining projects that would be perfect for digitally printed fabric, but am brought to an abrupt halt by my inability to sew. But that's probably for the best—my to-do list is pretty long and I stay behind as it is.

Q: A question for Kim: Stephen mentioned that you are part of a generation of women who has rediscovered domesticity and sewing (I think we’re the same generation—I’m 36, so I hope I’m not adding years on to you!). Can you talk about what this process of rediscovery has been like, and how technology has impacted it?

Kim Fraser: I'll be turning 40 this year so no offense taken! As far as rediscovering domesticity, I should say straight off that I've always been a huge homebody and have been interested in learning how to make the things that I need for as long as I can remember, from growing and canning my own food, cooking and baking, sewing my own clothes, and making items for my house. I only dabbled with sewing in college but got serious about it once I had children. I remember trying to shop for dresses for my very tall oldest daughter—age six at the time—and finding nothing in the stores that didn't just look cheap or much too old for her. I started sewing simple dresses for her out of fabric that I let her pick out. (A god-awful dress made from a large horse print springs to mind.) Then when I got pregnant with my second daughter, the nesting urge kicked in hard. That's when I started really sewing in earnest—quilts, baby bedding, stuffed toys, etc. I love making clothes for my girls, and I still get so much satisfaction out of feathering our "nest." It's much more gratifying than buying stuff off a shelf that has no soul and no personal meaning to us.

Technology I have mixed feelings about. On the one hand, it can be so inspiring to cruise around online looking at all the beautiful things that fellow sewists and crafters are making. I also have to admit that I've struggled with guilty feelings about my domestic bent and worried that such interests weren't terribly modern or enlightened. It's tremendously validating to know that there are literally thousands of other women out there who also share my interests. But on the other hand, the internet is a huge time suck! I often have to remind myself very sternly to shut the laptop and just make something already!

Q: Back to Stephen, where do you come up with all those wacky and wonderful contest themes?

Fraser: I usually come up with the contest themes late at night the evening before we send out our weekly contest email. We've now done well over a hundred contests, which means that I'm always looking for new ideas and often rely on suggestions from Spoonflower community members, Spoonflower staff, and Kim.

Q: What is the biggest challenge for Spoonflower right now?

Fraser: Our biggest challenge on any given day is typically managing the growth of our company using the limited resources we have. We have a small, very devoted and hard working team of people at Spoonflower who do an amazing amount to make our business run. And we're continuing to grow each month that goes by, which is very exciting—and never boring! We're looking forward to doing some new things this year, but the first task is always to make sure we can keep up with our core business, which is printing the fabric people order from us every day. Our next big announcement will involve a promotion we're doing with a major quilting fabric manufacturer, which I expect will generate a lot of excitement in the fabric-loving community.

RSS Feed

RSS Feed